What Size Rebar For Cinder Block Wall

Concrete blocks, too known as Concrete Masonry Units or CMUs, provide very durable structural and non-structural partitions. They are more often than not used as a fill-in wall that gets covered with a cease material or exposed in utilitarian spaces like mechanical rooms or basements. They can be painted to provide a cleaner cease, just they are also manufactured with unlike finishes that help improve the aesthetic quality over the traditional grey CMU.

- Nominal vs. Actual Dimensions

- CMU Sizes

- CMU Specifications

- CMU Shapes

- CMU Surface Finishes

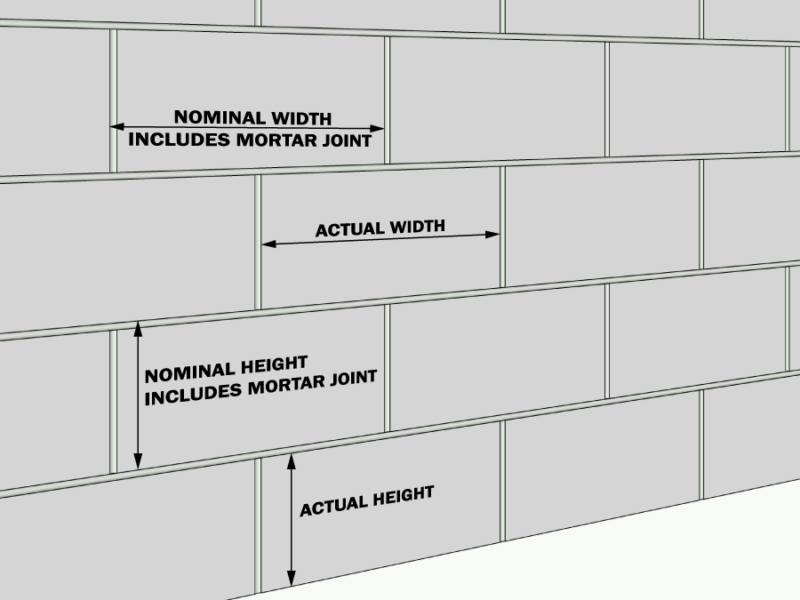

Nominal vs. Actual Dimensions

As with brick, CMUs accept bodily dimensions and nominal dimensions. Thenominal dimension of a CMU is theactual dimension plus the width of the mortar articulation. Typical CMU mortar joints are iii/8". The nominal dimension works within the 4" filigree that other construction materials follow. The graphic below shows the difference between nominal and bodily sizes.

Physical Block (CMU) Sizes

Concrete Masonry Units (CMUs) are manufactured in a variety of sizes. They are identified by their depth – i.due east. the thickness of the wall they create. For instance, a 6" CMU is nominally half-dozen" deep while a ten" CMU is nominally 10" deep.

Concrete blocks also come in half-sizes, which are helpful in reducing the need to cut blocks in the field at corners or the finish of walls. The architect should ever attempt to pattern buildings using the nominal dimensions to the nearest half-block size to reduce waste and labor due to cut blocks.

The following tabular array provides concrete cake sizes in both nominal and bodily dimensions. While 4", 6", 8", 10", and 12" are the standard sizes, some manufacturers offering other sizes not listed below.

| CMU SIZE | NOMINAL DIMENSIONS D 10 H X L (INCHES) | Actual DIMENSIONS D X H X L (INCHES) |

|---|---|---|

| iv" CMU Total Block | 4" x 8" x 16" | iii 5/8" x seven five/8" 10 15 5/8" |

| four" CMU Half-Block | 4" x 8" x 8" | 3 5/viii" x 7 5/viii" ten 7 v/8" |

| half dozen" CMU Full Cake | half dozen" x viii" x 16" | five 5/viii" x vii v/8" 10 15 five/eight" |

| 6" CMU Half-Block | 6" x 8" x 8" | 5 5/8" x vii five/viii" x vii v/8" |

| 8" CMU Full Block | 8" x 8" x 16" | 7 5/8" 10 vii 5/8" x 15 5/viii" |

| 8" CMU One-half-Block | 8" x viii" ten viii" | 7 v/8" x 7 5/8" x 7 5/8" |

| 10" CMU Full Block | ten" x 8" 10 sixteen" | 9 5/8" 10 7 5/8" ten 15 5/8" |

| ten" CMU One-half-Block | 10" 10 8" x 8" | ix 5/8" x 7 5/viii" ten 7 5/eight" |

| 12" CMU Full Cake | 12" x eight" x sixteen" | 11 5/8" ten 7 5/8" x 15 five/8" |

| 12" CMU Half-Cake | 12" x 8" 10 8" | eleven five/viii" x 7 5/8" ten seven 5/8" |

Concrete Masonry Unit of measurement (CMU) Specifications

CMU manufacturers must conform to ASTM standards when fabricating concrete blocks. The standards place appropriate materials, compressive strength, dimensional tolerance, wet absorption, and other functioning characteristics.

Concrete brick is made from concrete like to physical block, merely concrete bricks are fabricated in sizes that match traditional clay bricks (i.e. 2 2/3" tall).

The weight of physical masonry units varies depending on the density of concrete mix used. There are three classifications of CMU: lightweight (less than 105 lb/ft3), medium weight (between 105 lb/ftthree and 125 lb/ft, and normal weight (more than than 125 lb/ftiii. Lighter CMUs are less expensive, crave less labor to install, and tend to have ameliorate fire resistance properties. Heavier units tend to reduce sound transmission, have much college compressive strengths, and accept greater thermal storage chapters; nevertheless, they are more expensive and cost more to install. Architects must specify the CMU weight if a particular weight is required.

The following table provides the ASTM standards that apply to physical masonry units. ASTM C90 covers near conventional CMU structure and is the standard referenced by the ICC codes.

| ASTM DESIGNATION | TYPE OF CMU |

|---|---|

| ATSM C55 | Concrete Brick |

| ASTM C73 | Calcium Silicate Face up Brick |

| ASTM C90 | Load Bearing Concrete Masonry Units |

| ASTM C139 | CMUs for construction of Take hold of Basins and Manholes |

| ASTM C744 | Prefaced Concrete and Calcium Silicate Masonry Units |

| ASTM C936 | Solid Interlocking Concrete Paving Units |

| ASTM C1372 | Segmental Retaining Wall Units |

Concrete Masonry Unit (CMU) Shapes

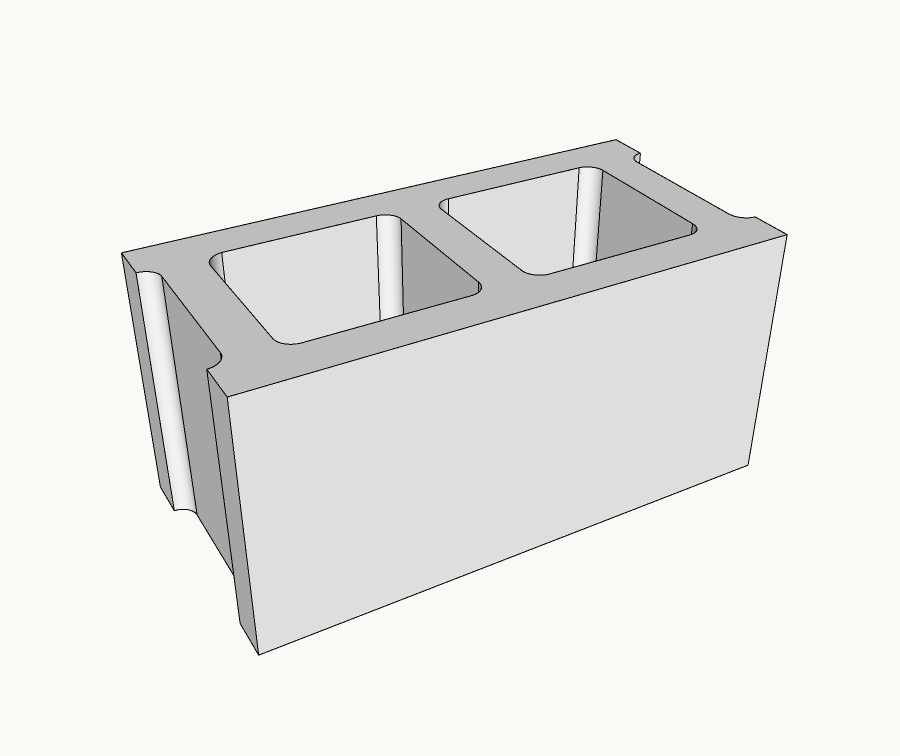

There are an well-nigh infinite number of CMU shapes available. The images below cover the nigh common shapes, just you should check with your local CMU manufacturer if yous demand special shapes or finishes.

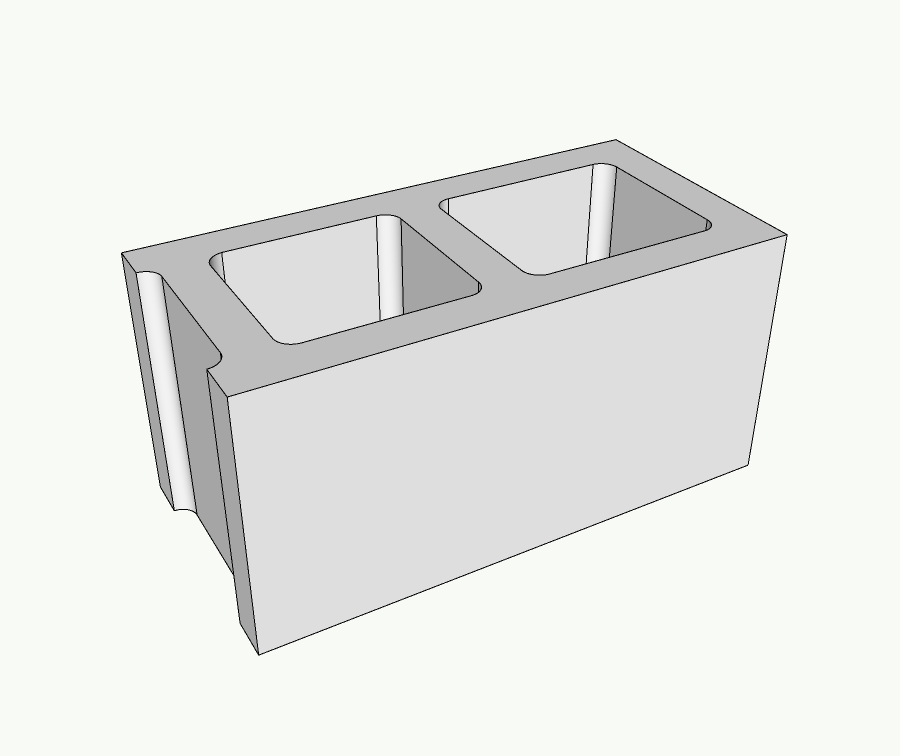

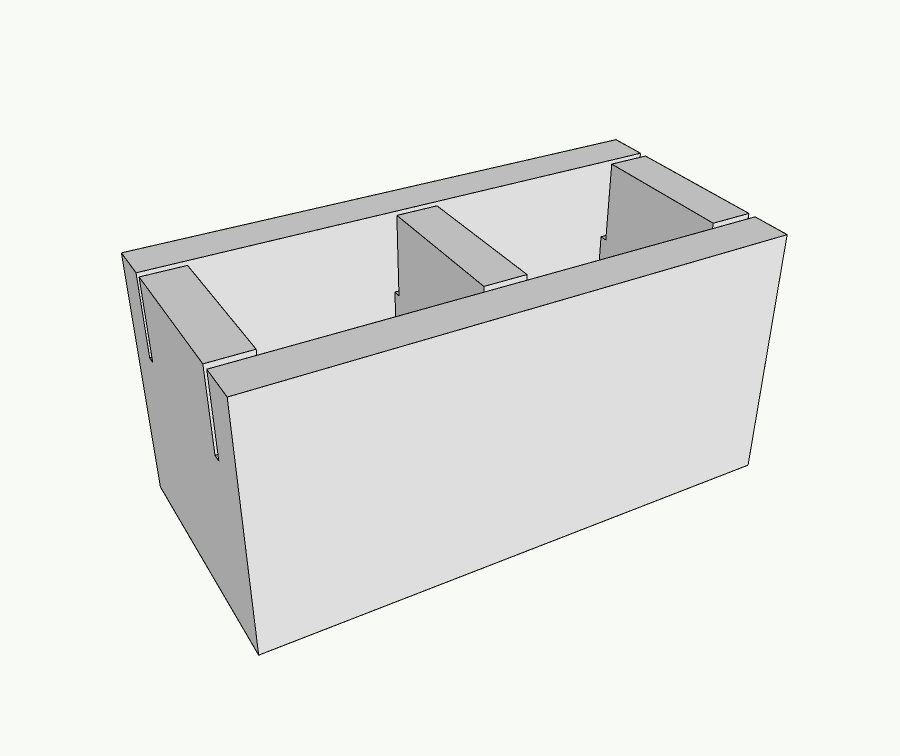

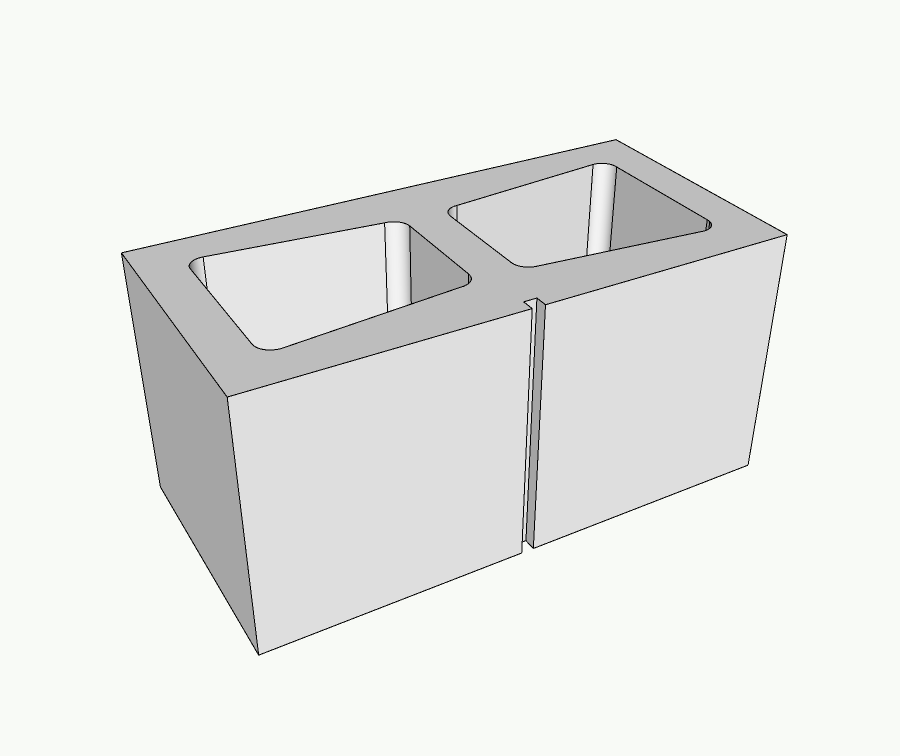

Stretcher

Kerf

Allows easy cutting

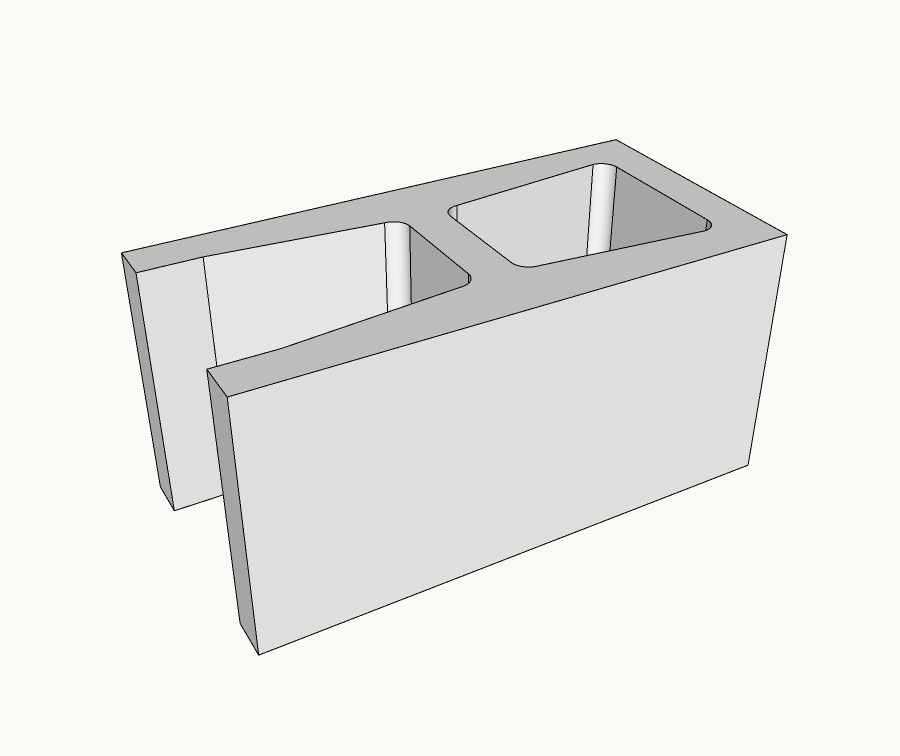

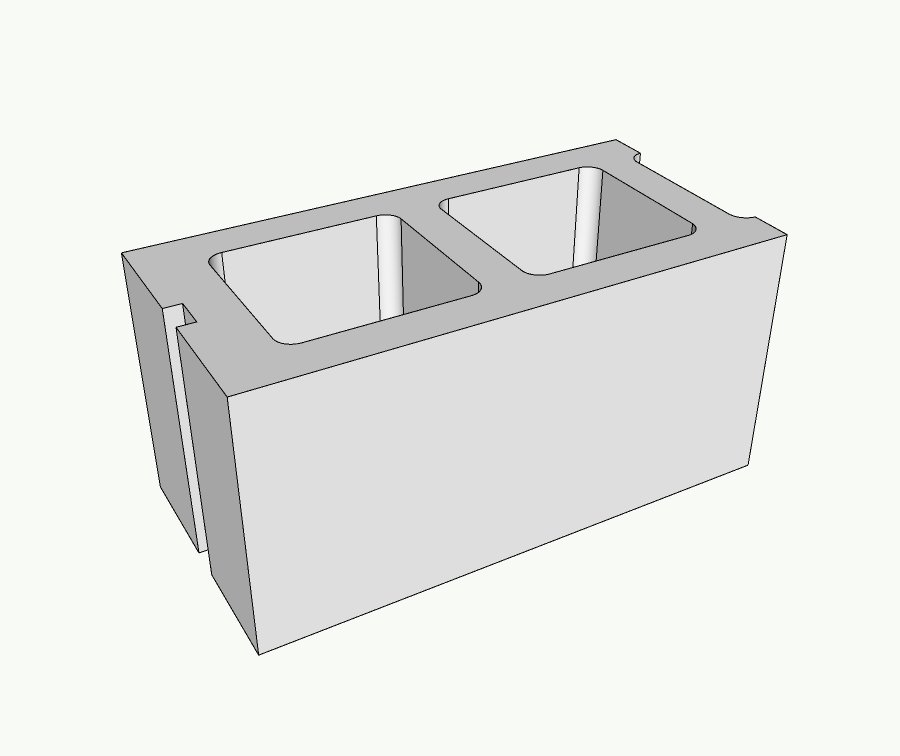

Double Corner

Single Corner

Open End

Allows for vertical reinforcing

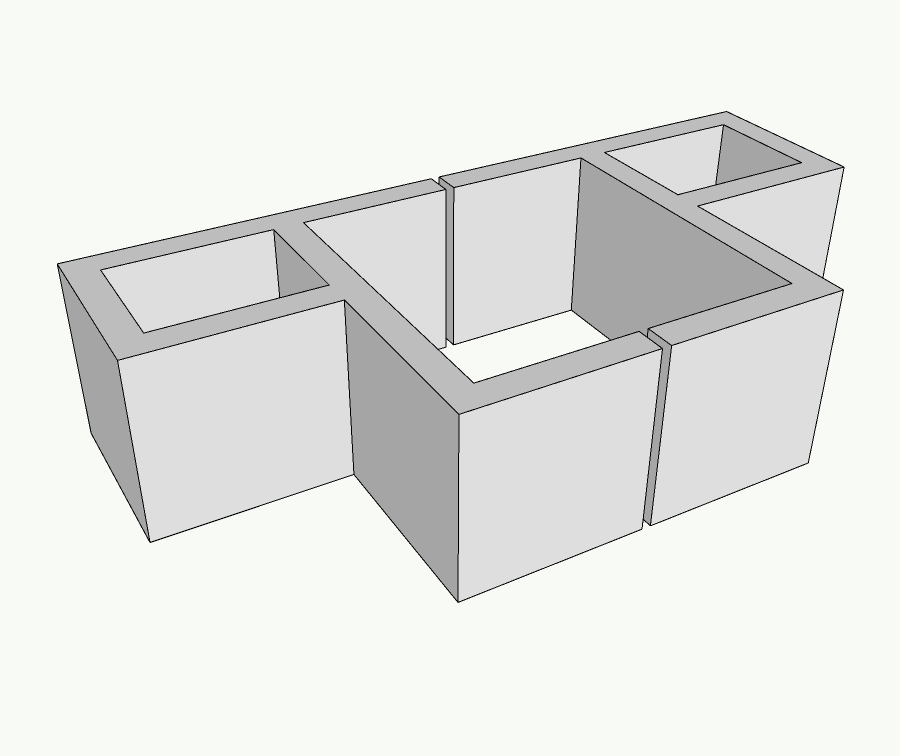

Double Open End

Allows for vertical reinforcing

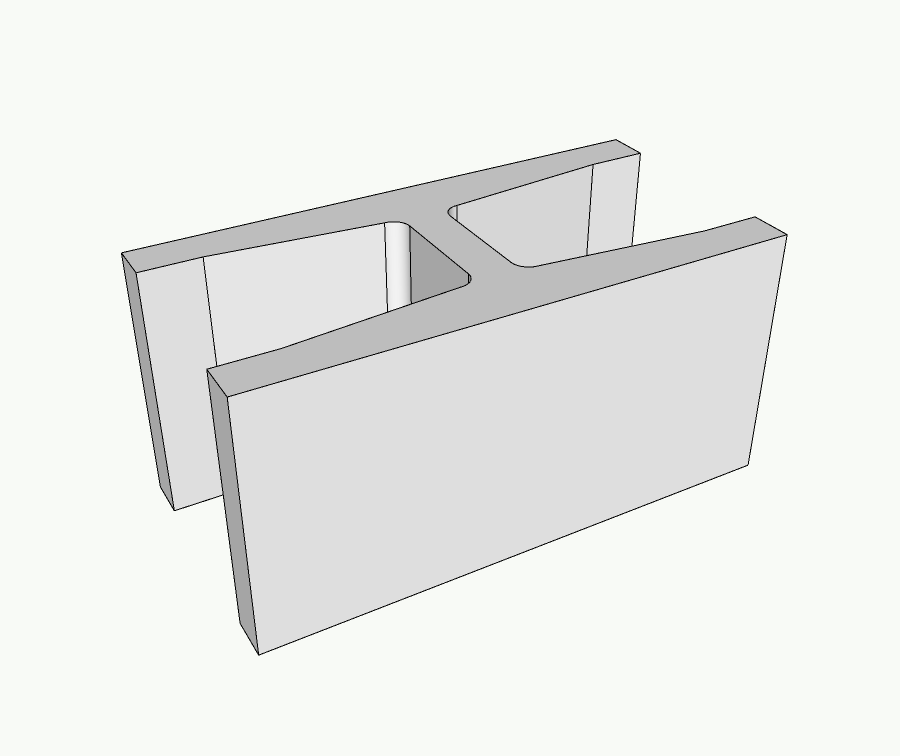

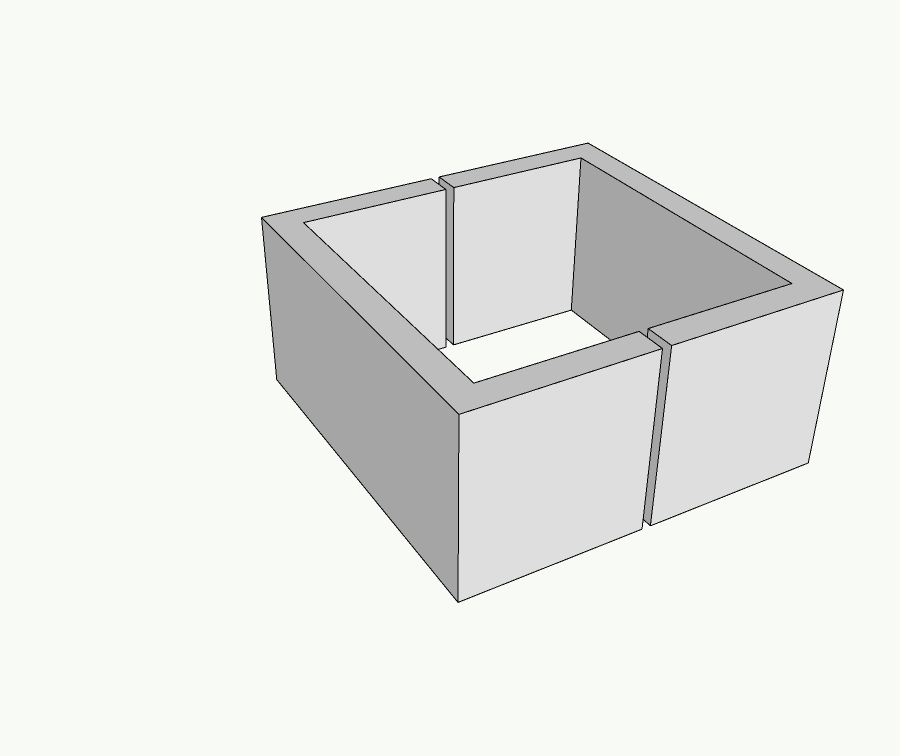

Bond Axle

Allows for horizontal reinforcing

Knockout Bond Axle

Allows mason to locate horizontal reinforcing

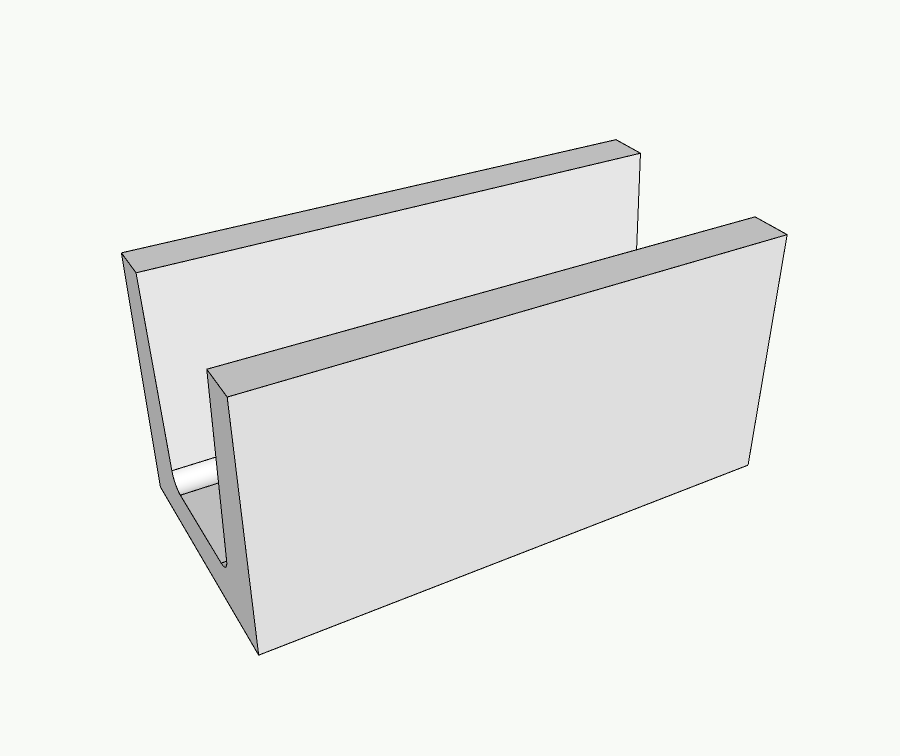

U Lintel

Allows horizontal reinforcing

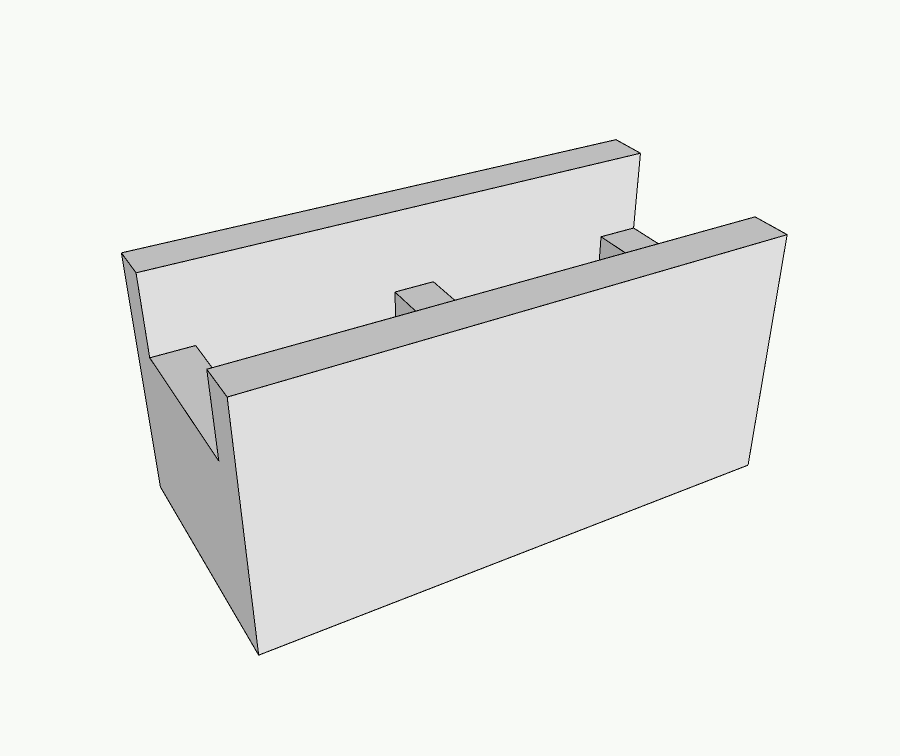

Sash

Allows control joint or door/window frame

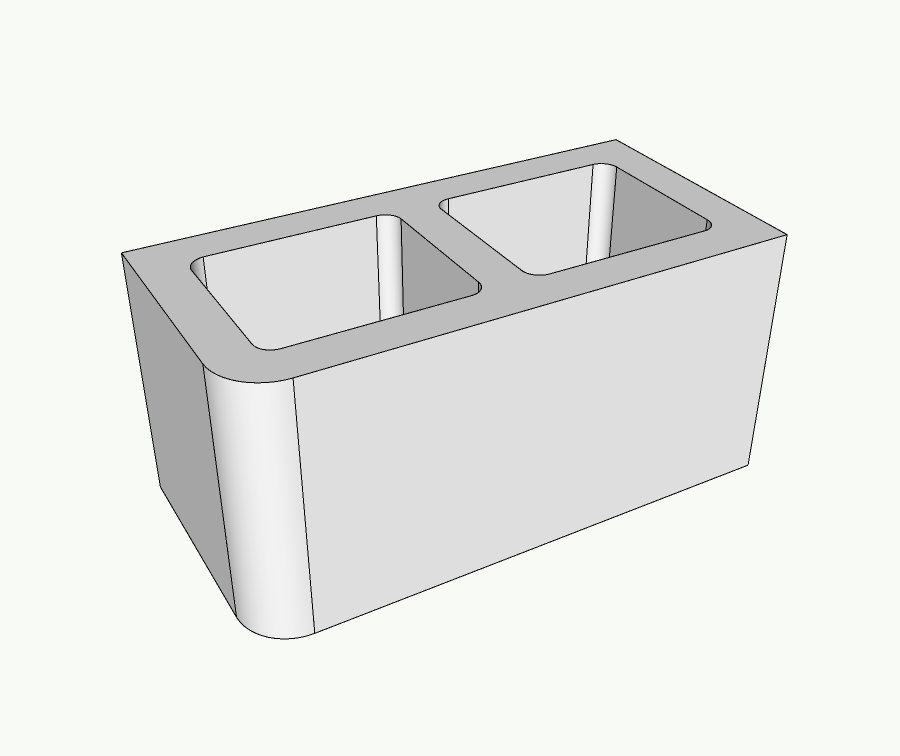

Bullnose

Radiused corner

Scored

Number of scores varies

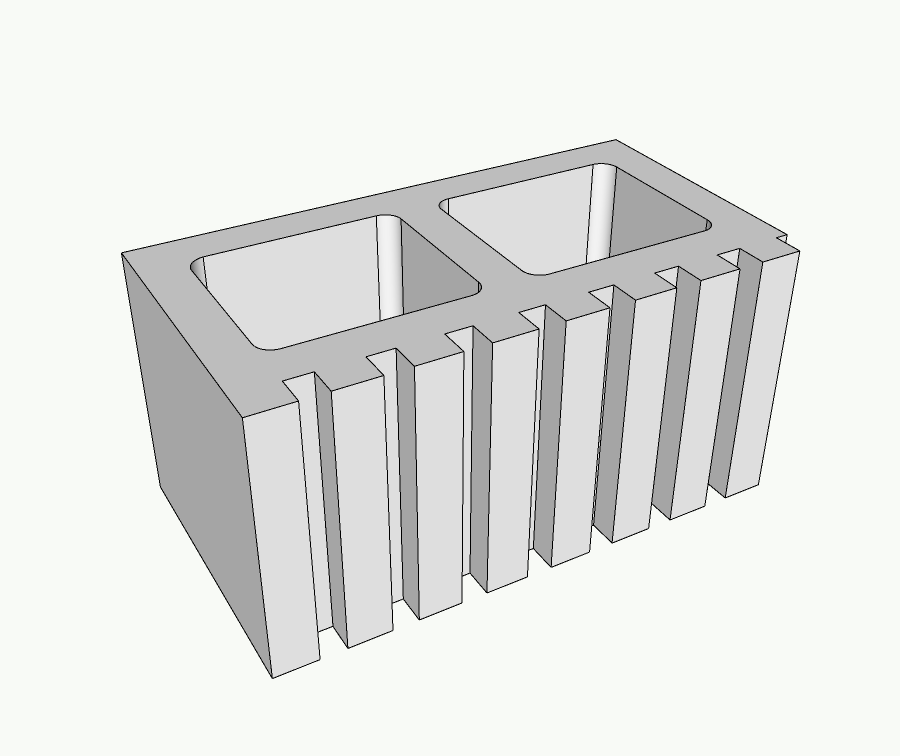

Ribbed

Number of ribs varies

Column

Comes in diverse sizes

Column with Pilaster

Comes in various sizes

Concrete Masonry Unit (CMU) Surface Finishes

As with shapes, there are a big number of finish options and so you tin can brand the utilitarian gray physical cake expect much more aesthetically pleasing. Be sure to run into with your local CMU representative to learn nearly what types of finishes they offer and at what price premium.

Colored CMU

Pigments can be added to both the concrete cake every bit well as the mortar. This allows for the cake and mortar to blend together or to have a precipitous contrast. Go along in mind that there volition be a natural variation in the color of the CMUs, even if they come from the same manufacturing batch. Therefore, it is important that the builder review at least 3 sample blocks that demonstrate the expected color variation.

If the colour needs to exist consistent or verbal, you may consider painting the cake and mortar. Painting is by and large done on the interior, but can also be accomplished on exterior surfaces. Be sure to work with your CMU manufacturer and pigment supplier to select the right pigment for your situation.

Glazed CMU

Glazed CMU has a tile-like glazed finish made from a resin-based coating. The blanket offers a wide multifariousness of color as well every bit some fake material patterns. These surfaces may offer improved resistance to graffiti and chemicals. Glazed CMU is covered via ASTM C744, but the blocks notwithstanding need to adhere to the ASTM C90 standard for load bearing CMU.

Divide Faced CMU

Split faced CMU is manufactured by molding two units side-by-side and then mechanically splitting them apart after firing. This creates a very rough texture that some people recollect looks similar stone, especially since the aggregates in the block are also split or exposed.

Ribbed or scored units (graphics above in the Shapes section) tin also have a split faced stop to add more texture.

Soft-Split up CMU

Soft-Split CMU is fabricated with special molds that create a split-faced advent instead of mechanically splitting the blocks. The result is a bit less crude than split faced. In addition, the mold means that aggregates are not exposed.

Glassy or Polished CMU

Also referred to as Basis Confront CMU, concrete blocks can exist burnished or polished to expose the natural aggregates in the concrete mix. It is important to piece of work with the manufacturer to select appealing aggregate and to test the polishing process to ensure you go the artful you are looking for.

Sandblasted CMU

Sandblasting physical masonry units also exposes the amass, but likewise blasts abroad some of the sand and cement to create a rougher advent. Some people believe this creates a natural weathered look instead of the smoother await of burnished or polished CMU.

Raked CMU

Raked (or Striated) units accept vertical rake marks introduced during the molding process. The rake marks are not equally deep every bit the scored or ribbed blocks identified in a higher place in the Shapes section, but they practice add an appealing texture to the block. Yous can also specify that scored or ribbed blocks have an additional raked pattern applied for more than texture.

Commodity Updated: May 16, 2021

Aid brand Archtoolbox better for everyone. If you found an fault or out of date data in this commodity (even if it is just a modest typo), please let us know.

What Size Rebar For Cinder Block Wall,

Source: https://www.archtoolbox.com/cmu-sizes-shapes-finishes/

Posted by: hendersonplat1974.blogspot.com

0 Response to "What Size Rebar For Cinder Block Wall"

Post a Comment